Biochar is a material made from charcoal that helps soil improvement and it is beneficial to plants. The charcoal is made by burning crops and wood residues.

You can turn these crop and wood residues through simple processes to achieve amazing material. A material capable of improving soils and yields. The commercial production of biochar is a whole enterprise on its own.

Read also:

What Is Biochar? The Remarkable Material For Soil Improvement And An Alternative To Fossil Fuel

We shall take you through how to prepare biochar, in this post. You do not need to be an expert.

Materials you need to prepare biochar

- Crop residues (maize husk, maize cob, coconut shells, cocoa pods etc.)

- Wood residues (sawdust, fallen branches of trees, leaves of trees etc.)

- Food waste.

- A Multifeed Gasifier Stove (MFGS).

Steps to prepare biochar

- Put any available crop or wood residue into the MFGS and burn under very hot temperatures for 2-3 hours.

- Let it cool and pour out the burnt input on a flat surface or into a sack.

- Use a roller pin to further smoothen it into a powder form.

- Your biochar is ready

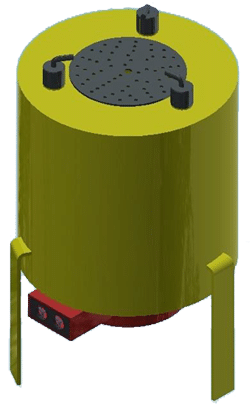

The Multifeed Gasifier Stove (MFGS) allows you to burn the biomass with no oxygen entering the stove.

Below is how a Multifeed Gasifier Stove looks like.

Read also:

Earthworm Types and Benefits to Soil Fertility and Plants in Agriculture

Note: The MFGS is like a normal “Gyapa stove“. However, the MFGS has inner chambers where the biomass is burnt. It is relatively inexpensive and a farmer can quite easily get one.

But, if you cannot afford an MFGS, you can burn the biomass. Just make sure you cover it with a metallic barrel or container. So that it is not exposed to oxygen to form ash. If the biomass is maize husks or even farm weeds, if you burn them well it should look like the picture below.

It may not be as smooth as the above picture. You may have to make it smooth with a rolling pin or stone.

Pellets (Biomass charcoal) and Pelletizers

Pellets

They are biofuels made from compressed biomass. You can make pellets form any one of five general categories of biomass;

- Industrial waste and co-products,

- Food waste,

- Agricultural residues,

- Energy crops, and

- Virgin biomass.

Wood pellets are the most common type of pellet fuel and are generally made from compacted sawdust. Other waste sources include empty fruit branches, coconut shells, rice husks and corn husks which aids in the production of the pellets.

Read also:

Soil Structure and the Factors Affecting Soil Structure

Black pellets are made of biomass, refined to resemble hard coal and are developed to be used in existing coal-fired power plants. You can use them as fuels for cooking using the gasifier stove. The pellets used for the gasifier stove as a fuel are extremely dense and you can produce with a low moisture content (below 10%) that allows them to burn with a very high combustion efficiency.

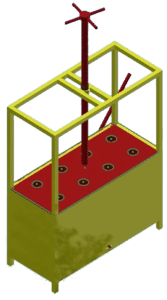

Pelletizers

They are used for the production of biomass pellets from a mixture in its powdered form. They are of diverse types and forms ranging from their sizes, shapes, the method of operation (manual or automatic), capacity and function.

Below is how a simple hand pelletizer looks like.

Materials needed in pellets production

- Biochar

- Pelletizer

- Starch

Procedure

- Mix the char with starch. Feed into the mould in the compaction chamber. Ram until they are full.

- Close the cover plate of the machine, screw to tighten.

- Open the cover plate of the machine. Remove the pellets and dry.

Note: You can make the starch yourself. Add cassava dough and lots of water to the char and stir on the fire till it turns very sticky and light.

Read also:

Soil Conservation: How to maintain Soil for Sustainable Crop Production

If you also cannot get a pelletizer, you can mould them with your hand and dry.

Below is a sample of what the pellets will look like.

Benefits of pellets

- The pellets are less smoky than charcoal.

- Pellets need fewer places to store and handle.

- They are more hygienic than normal charcoal.

- Substituting charcoal with pellets means a lower rate of deforestation and land degradation.